Internet Explorer, Chrome Browser, Firefox Browser, Safari Browser

Siemens at the SPS IPC Drives 2017

Nuremberg, 28 November to 30 November 2017

Save the date2017-11-28T00:00:002017-11-30T00:00:00Europe/Parisuse-titleSiemens at the SPS IPC Drives 2017New MindSphere Version 3.0 on Amazon Web Services (AWS) provides access to Siemens APIs and AWS cloud services for faster developmentSimotics IQ: New IoT concept for motorsNew partnership financing service to boost the implementation of Industrie 4.0Study affirms annual productivity increase due to digitalization of up to 9.8 percentNuremberg

Digitalization is changing our world – and the world of industry – in tangible ways. The digital transformation is creating new competitive advantages and business models in many companies in the manufacturing and process industry. Machine builders and plant engineers can also take advantage of this development and make it usable for their customers. For digital enterprises systems and processes can be comprehensively and uniformly optimized throughout the entire lifecycle of products and plants. At the SPS IPC Drives in Nuremberg, Germany, from November 28 to 30, 2017 – which took place this year under the motto "Discover the value of the Digital Enterprise" – Siemens presented in hall 11 specific examples of applications to show how this can be done.

Save the date2017-11-28T00:00:002017-11-30T00:00:00Europe/Parisuse-titleSiemens at the SPS IPC Drives 2017New MindSphere Version 3.0 on Amazon Web Services (AWS) provides access to Siemens APIs and AWS cloud services for faster developmentSimotics IQ: New IoT concept for motorsNew partnership financing service to boost the implementation of Industrie 4.0Study affirms annual productivity increase due to digitalization of up to 9.8 percentNuremberg

Digitalization is changing our world – and the world of industry – in tangible ways. The digital transformation is creating new competitive advantages and business models in many companies in the manufacturing and process industry. Machine builders and plant engineers can also take advantage of this development and make it usable for their customers. For digital enterprises systems and processes can be comprehensively and uniformly optimized throughout the entire lifecycle of products and plants. At the SPS IPC Drives in Nuremberg, Germany, from November 28 to 30, 2017 – which took place this year under the motto "Discover the value of the Digital Enterprise" – Siemens presented in hall 11 specific examples of applications to show how this can be done.

Press Release28 November 2017

Industrie 4.0: The hour of implementation has arrived

- New MindSphere Version 3.0 on Amazon Web Services (AWS) provides access to Siemens APIs and AWS cloud services for faster development

- Simotics IQ: New IoT concept for motors

- New partnership financing service to boost the implementation of Industrie 4.0

- Study affirms annual productivity increase due to digitalization of up to 9.8 percent

Press Release18 October 2017

Siemens showcases digitalization applications for machine and plant builders

- Extended Digital Enterprise portfolio for discrete and process industries

- Machine and plant builders use digitalization to develop new business models and speed up time-to-market

- Digitalization applications enhance flexibility, efficiency and quality

- Extended "MindSphere-Lounge" over an area of 1,400 square meters

Press conference at the SPS IPC Drives 2017

Product Pictures

Temperature measuring system lengthens the service lives of plants and improves product quality

In the Sitrans TO500, Siemens is putting an innovative measuring system for fiber-optic temperature measurement onto the market. It enables complex temperature measurements and detection of the precise position of critical overtemperatures, for example in tube and tube-bundle reactors. The Sitrans TO500 is characterized by a large number of measuring points (up to 48 per measuring lance, depending on the temperature range) and the small diameter of the sensor measuring lance.

Siemens process control system first product with IECÂ 62443 security certification

Siemens is the first company to obtain security certification from TĂśV SĂśD (German inspection and certification organisation) for an automation system based on IECÂ 62443-4-1 and IECÂ 62443-3-3. For the product certification according to IECÂ 62443-4-1 and 62443-3-3, TĂśV SĂśD tested and verified the security functions implemented in the Simatic PCS 7 process control system.

Slimline design with multi-touch, user-friendly operation for industry

Siemens is complementing its industrial operator control and monitoring devices with new Simatic Flat Panel monitors and Simatic Panel PCs in multi-touch, 16:9 widescreen format. The new versions are the Simatic Panel PC IPC277E with 15 and 19 inch displays, and the Simatic Panel PC IPC477E and Simatic Flat Panel IFP monitors with 15, 19 and 22 inch displays.

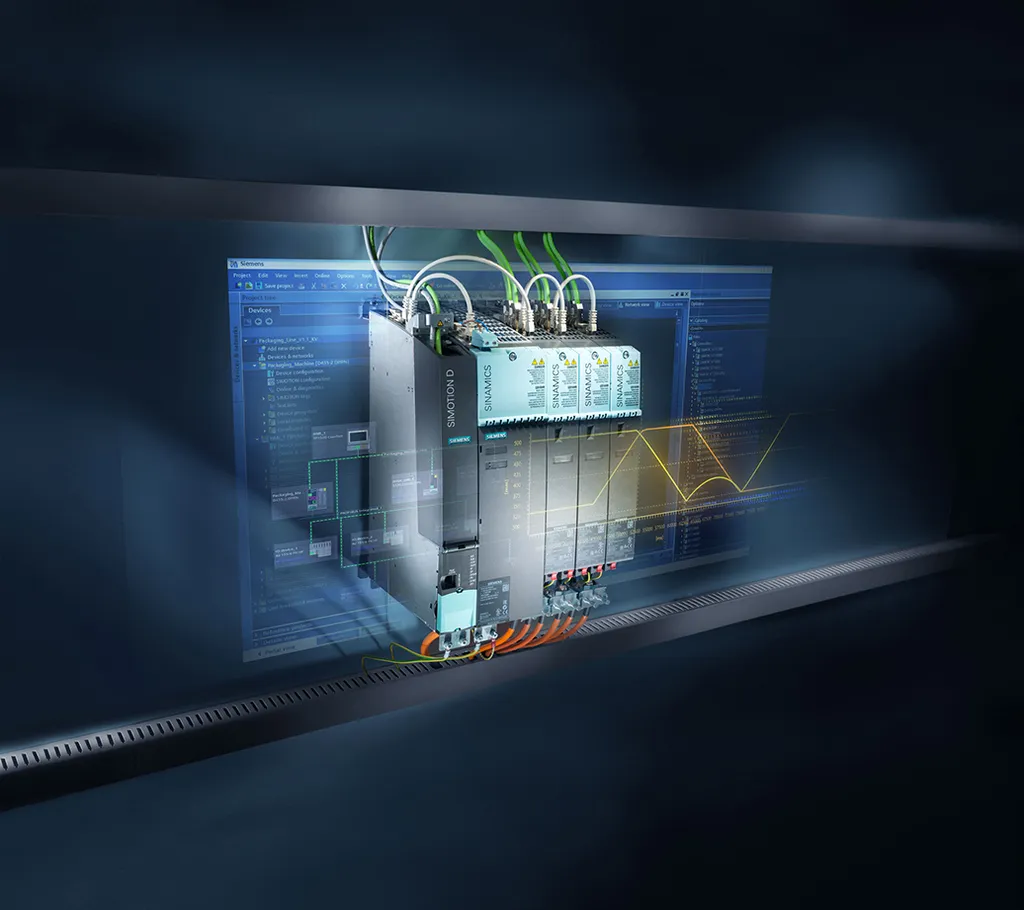

Efficient approach to demanding motion control solutions with new software

Siemens has updated the software for its high-end motion control system Simotion and, in the new Version 4.5, has equipped it with object-oriented programming (OOP) and communication via OPC UA (Open Platform Communications Unified Architecture). Thus, mechanical engineers can now implement large software projects much more efficiently than before and can now access Simotion data in a standardized way, across all automation levels – as far as the Cloud.

Substantially more possible applications for Siemens logic modules

Siemens has substantially widened the range of possible applications for the current Logo! 8 logic module series. The temperature range has been extended down to minus 20 degrees Celsius to allow the logic module to be used for the first time at sub-zero temperatures.

Siemens extends high-voltage motor portfolio to include new series up to 70 MW

A flexible modular concept enables precisely tailored solutions in all kinds of industrial applications in the high power range: With the new Simotics HV HP high-voltage motor series, Siemens is now able to cover an extended power range of up to 70 MW.

RFID system simplifies access control for operating personnel at machines and plants

With its new Simatic RF1000 RFID system, Siemens is offering a flexible, simple solution to monitor access to machines and plants using the new Simatic RF1060R reader – the first device of its type on the market. It enables companies to use existing employee ID badges to identify operating personnel and to document the access to plants and machines.

Industrial Ethernet switches for reliable communication in automation

With its Scalance XC-200 product line, Siemens is bringing a new generation of compact Industrial Ethernet switches onto the market. Users can use them to set up electrical and optical line, star and ring structures in industrial networks. The layer 2 network components can be integrated into both Profinet and EtherNet/IP diagnostics.

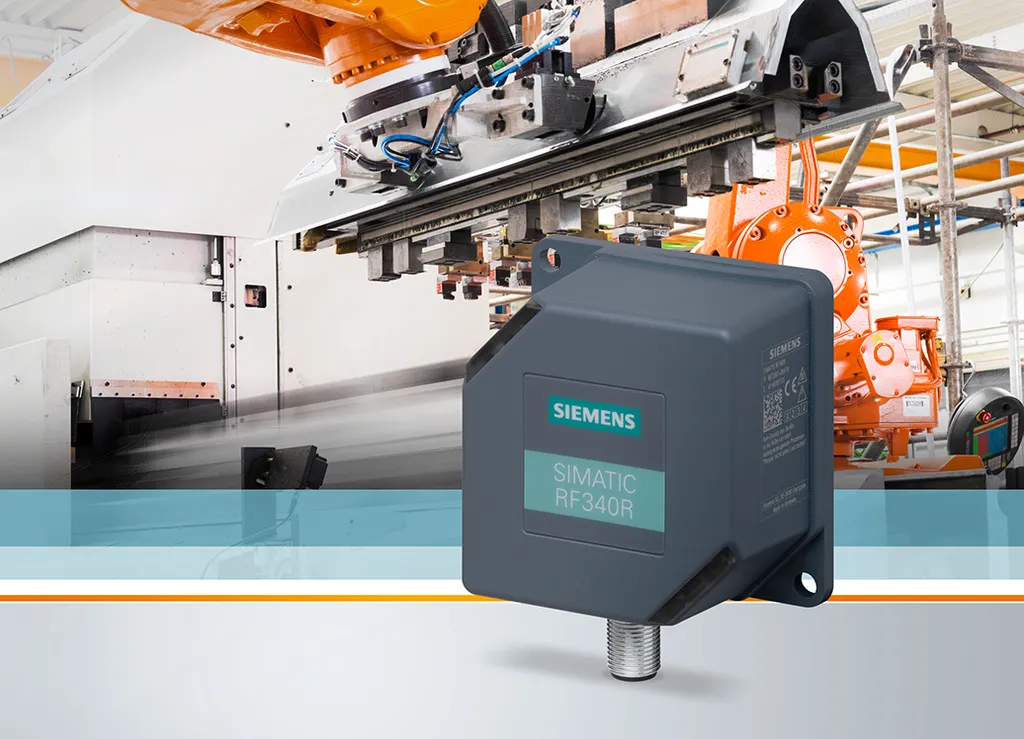

New RFID reader generation for flexible applications

Siemens has modernized its Simatic RF300 RFID system by adding three new readers: RF310R, RF340R and RF350R. They are integrated into the Simatic Step 7 engineering systems and the TIA Portal to make commissioning easy. The new readers offer an additional transponder protocol (air interface) for MOBY E transponders (MIFARE classic, ISO 14443 A) and automatic recognition of various types of transponder (RF300, ISO 15693, MIFARE classic).

Temperature measuring system lengthens the service lives of plants and improves product quality

In the Sitrans TO500, Siemens is putting an innovative measuring system for fiber-optic temperature measurement onto the market. It enables complex temperature measurements and detection of the precise position of critical overtemperatures, for example in tube and tube-bundle reactors. The Sitrans TO500 is characterized by a large number of measuring points (up to 48 per measuring lance, depending on the temperature range) and the small diameter of the sensor measuring lance.

Siemens process control system first product with IECÂ 62443 security certification

Siemens is the first company to obtain security certification from TĂśV SĂśD (German inspection and certification organisation) for an automation system based on IECÂ 62443-4-1 and IECÂ 62443-3-3. For the product certification according to IECÂ 62443-4-1 and 62443-3-3, TĂśV SĂśD tested and verified the security functions implemented in the Simatic PCS 7 process control system.

Slimline design with multi-touch, user-friendly operation for industry

Siemens is complementing its industrial operator control and monitoring devices with new Simatic Flat Panel monitors and Simatic Panel PCs in multi-touch, 16:9 widescreen format. The new versions are the Simatic Panel PC IPC277E with 15 and 19 inch displays, and the Simatic Panel PC IPC477E and Simatic Flat Panel IFP monitors with 15, 19 and 22 inch displays.

Efficient approach to demanding motion control solutions with new software

Siemens has updated the software for its high-end motion control system Simotion and, in the new Version 4.5, has equipped it with object-oriented programming (OOP) and communication via OPC UA (Open Platform Communications Unified Architecture). Thus, mechanical engineers can now implement large software projects much more efficiently than before and can now access Simotion data in a standardized way, across all automation levels – as far as the Cloud.

Substantially more possible applications for Siemens logic modules

Siemens has substantially widened the range of possible applications for the current Logo! 8 logic module series. The temperature range has been extended down to minus 20 degrees Celsius to allow the logic module to be used for the first time at sub-zero temperatures.

Siemens extends high-voltage motor portfolio to include new series up to 70 MW

A flexible modular concept enables precisely tailored solutions in all kinds of industrial applications in the high power range: With the new Simotics HV HP high-voltage motor series, Siemens is now able to cover an extended power range of up to 70 MW.

RFID system simplifies access control for operating personnel at machines and plants

With its new Simatic RF1000 RFID system, Siemens is offering a flexible, simple solution to monitor access to machines and plants using the new Simatic RF1060R reader – the first device of its type on the market. It enables companies to use existing employee ID badges to identify operating personnel and to document the access to plants and machines.

Industrial Ethernet switches for reliable communication in automation

With its Scalance XC-200 product line, Siemens is bringing a new generation of compact Industrial Ethernet switches onto the market. Users can use them to set up electrical and optical line, star and ring structures in industrial networks. The layer 2 network components can be integrated into both Profinet and EtherNet/IP diagnostics.

New RFID reader generation for flexible applications

Siemens has modernized its Simatic RF300 RFID system by adding three new readers: RF310R, RF340R and RF350R. They are integrated into the Simatic Step 7 engineering systems and the TIA Portal to make commissioning easy. The new readers offer an additional transponder protocol (air interface) for MOBY E transponders (MIFARE classic, ISO 14443 A) and automatic recognition of various types of transponder (RF300, ISO 15693, MIFARE classic).

Temperature measuring system lengthens the service lives of plants and improves product quality

In the Sitrans TO500, Siemens is putting an innovative measuring system for fiber-optic temperature measurement onto the market. It enables complex temperature measurements and detection of the precise position of critical overtemperatures, for example in tube and tube-bundle reactors. The Sitrans TO500 is characterized by a large number of measuring points (up to 48 per measuring lance, depending on the temperature range) and the small diameter of the sensor measuring lance.